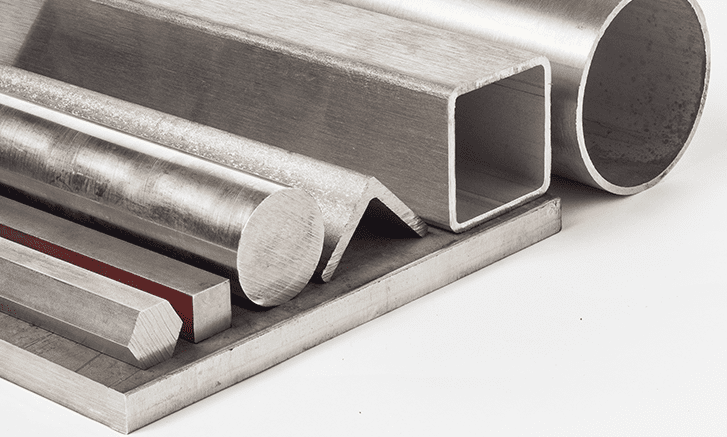

Both steel (carbon steel) and stainless steel are the essential metal materials used in the majority of metal industries. To understand the various metalworking processes and parts, differentiating between the two is critical.

Due to the various material combinations, these two metals have different properties that determine durability and usage.

This article uncovers everything you need to know about steel and stainless steel. Read on!

Steel

Also known as carbon steel, steel is an alloy of iron and about 2% carbon. The low percentage of carbon provides huge variations in physical features.

The usual talk of carbon steel is mostly referenced to the high carbon industrial steel used in making various tools and knives. These steels are very sturdy, and hence suitable for shape-retaining and abrasion resistance. Carbon steels do withstand substantial force before distorting or losing shape.

The downside, however, is that majority of hard metals, including carbon, are very brittle. In the event these metals are subjected to extreme tensile stress, they are likely to crack, unlike soft metals that do bend.

When compared with their high carbon counterparts, low carbon steels are more popular due to the following reasons:

- They have greater ductility

- It’s cheaper to produce low carbon steels

- They don’t require complex manufacturing processes

Low carbon steels usual deform or bend when subjected to stress rather than breaking. Due to the low ductility, low carbon steels easy to weld and operate mechanically. These steels are often used in to make bolts, steel plates, fixtures, and automobile body panels.

Stainless Steel

Mainly, stainless steel is used the manufacture of household items including utensils, faucets and taps. These items function exceptionally well in wet surroundings without rusting.

Stainless steel comprises of carbon, iron and more than 10.5% chromium. Chromium is an essential element that reacts creates a protective layer to cushion steel from corrosion. This protective layer reduces the possibility of rusting, which makes stainless steel a vital tool for the manufacture of for tools used in wet environments. Higher chromium levels mean higher corrosion resistance and vice versa.

Chromium is the more significant player in stainless steel. Tools with low chromium levels are cheaper with less durability while those with more than 16% of chromium being more expensive and highly durable.

Grades of Stainless Steel

Often, manufactures produce different grades of stainless steel. These different grades are suited for various functionalities and have differing applications. Each grade of stainless steel is determined by stain resistance levels. Different amounts of chromium and carbon are used for different grades.

Carbon Steel vs Stainless Steel

High-carbon steel is always used for the manufacture of sturdy kitchen knives for high-end application. The reason for this is that it has strong wear resistance. Blades with high levels of wear resistance usually stay sharper longer than average. Automotive parts that are mainly subjected to wear and tear are made of carbon steels.

On the other end, stainless steel is applied mostly in appliances used in water. Stainless steel has high corrosion resistance and might not rust even after the long periods of use.

Metalworkers can use allow elements such as silicon, nickel, molybdenum, and chromium to increase steel’s corrosion resistance as well as achieve a balance between toughness and strength.

The Bottom Line

When it comes to durability, both steel and stainless steels are highly durable. The big difference, however, is in terms of wear and corrosion resistance. With high chromium content, stainless steel does not rust but can wear quickly when used in wear and tear equipment. Carbon steel more robust and more durable and might not wear easily but can corrode and rust when exposed to moisture.

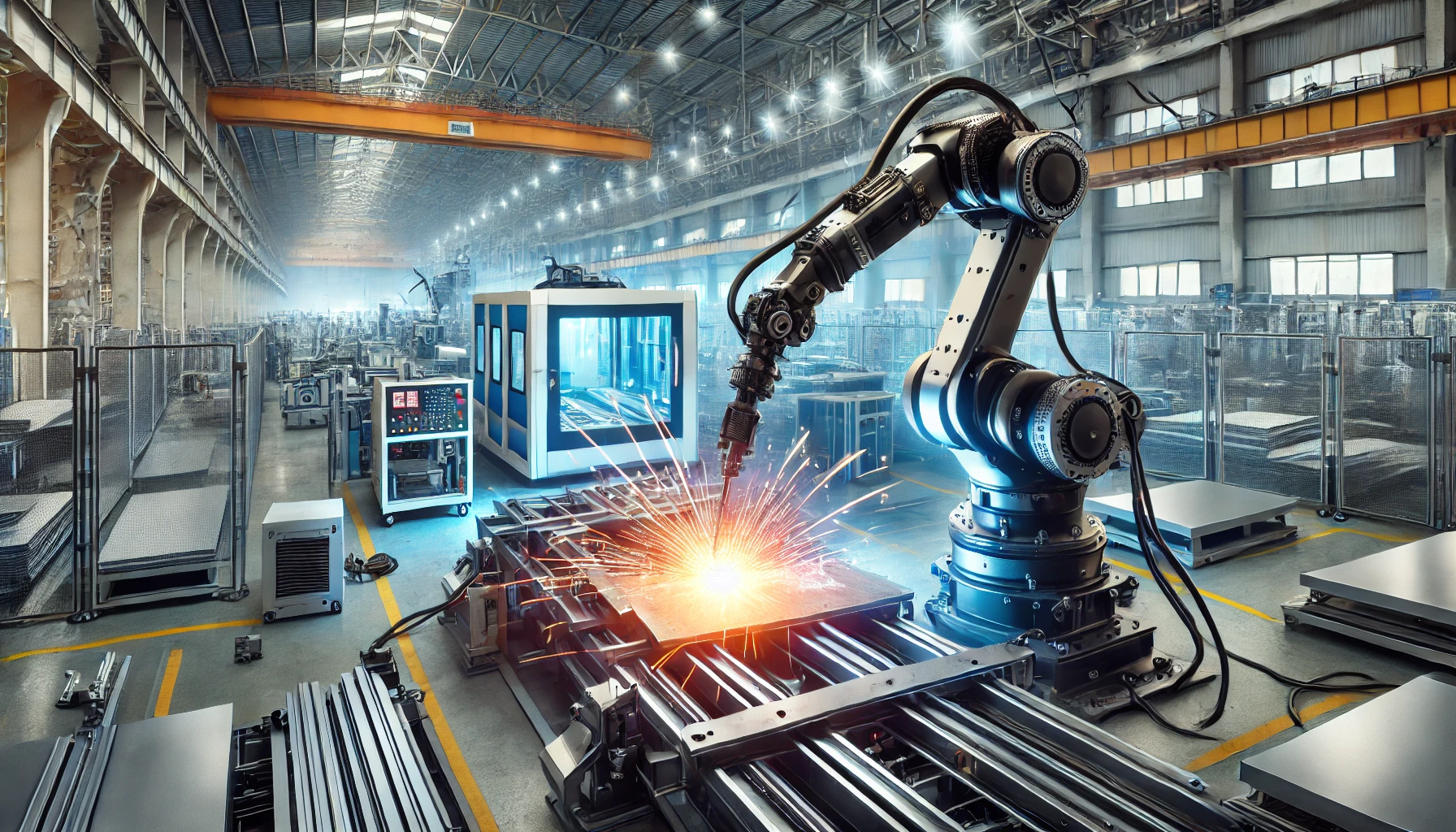

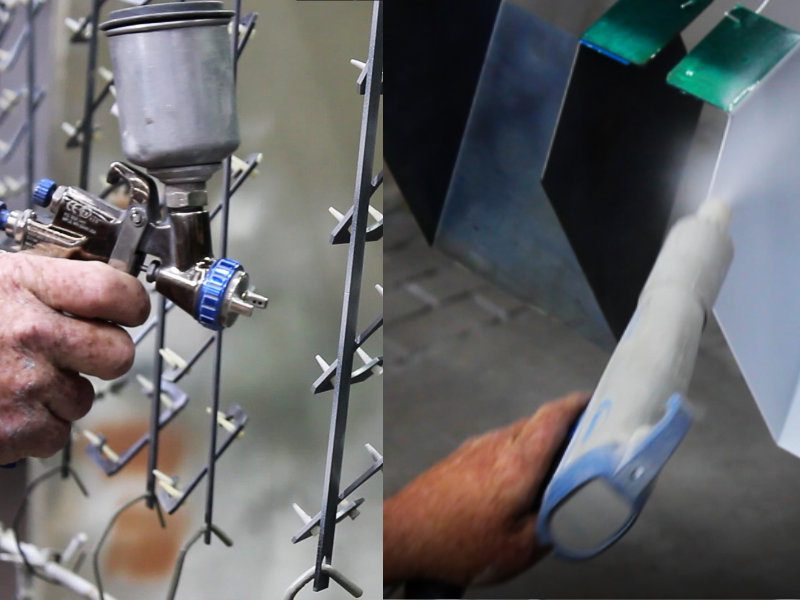

Check out our engineering capabilities or get in touch with our experts for your metalworking endeavors.