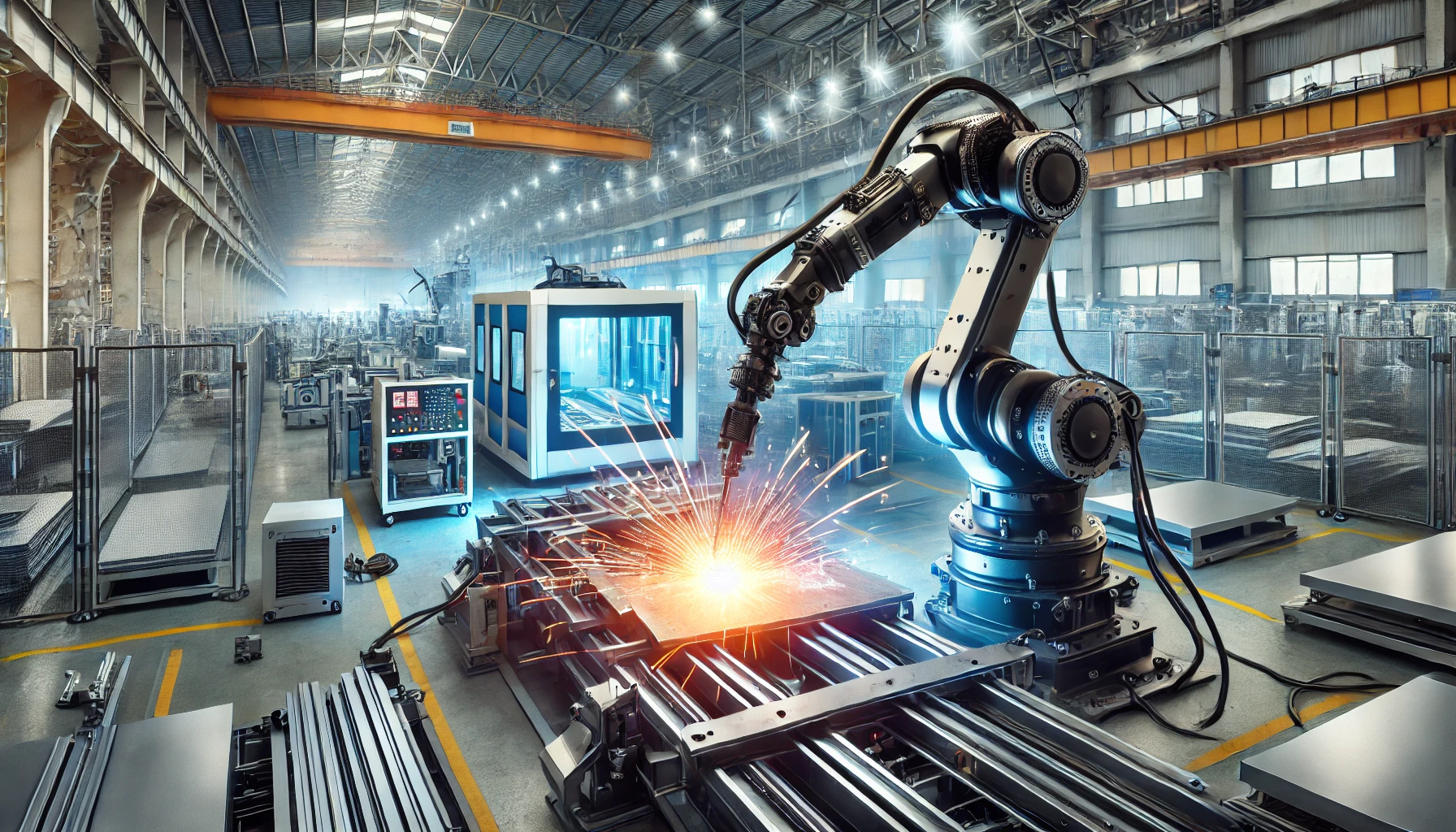

Welding is a process where there are two or more pieces of metal or thermoplastics that are fastened together using heat and pressure. A variety of factors is involved with the process of welding, but the form and thickness of the material is the deciding factor for which method is the most effective. Metal Inert Gas (MIG), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) are some common types of welding used today.

With today’s technology, many operators might forget essential steps when performing a weld. If these operators run into trouble, they might not be able to figure out quickly what the problem could have been.

Porosity

Porosity is cause by the absorption of nitrogen, hydrogen, and oxygen in the molten weld pool which is then released on solidification that would become trapped in the weld of the metal. The presence of moisture, grease, rust, paint on the plate edges, or when there are small gaps of air in between of the weld are some causes for porosity. To avoid this in a weld, the operator should re-bake, use fresh consumables, and check the welding torch for any leaks. Having a clean and dry plate edges can help as well. Be sure to double check your flow rates, the shielding gas type, and having a clean gas nozzle.

Deformation

Deformation happens when the contraction of welded metals during the cooling and hardening phase. The welding sequence is not suitable for the intended weld, poor plate fit-ups, and too many thin beads before welding. Some things to avoid deformation can be welding from both sides of the joint, using larger electrode and clamping firmly, and welding from the center out. With the change of the sequences of the welds, making few passes, and the location of the joint can help reduce the risk.

Undercut

Undercutting occurs when the arc voltage is high or when the arc is too long. If there is incorrect electrode usage or angle, and the electrode is too large for the thickness of the plate this could also happen. Undercuts tend to happen if the speed is too quick when traveling. When watching the speed, its important to check for proper manipulation of the electrode when used. Try not to use a bigger than needed electrode because if the amount of molten metal is too big, there would be an undercut.

Cracks

Every crack regardless of any size is considered a defect. This can be dangerous because of the small cracks that have the potential to become larger cracks over time. This is something that you can’t just fill the gap of the crack because it would have to be grounded out and then a new weld would be put into place. To avoid cracks when welding, its necessary to spend time on cleaning, grinding, filing, or deburring the edges of the plates. This way they easily fit together. Take your time and you will eliminate these chances.

Wire Delivery

Having the correct setup of the equipment and maintenance is just as important as to just welding and getting it done. Sometimes you might hear chattering sounds within the gun cable because there could be an issue with the wire delivery system. Check your equipment before you start your weld process. Having the correct size of tips will help eliminate this as well. Having too large of a tip can lead to other issues as listed above. Its good practice to checking the tip of the wire to see if it’s worn out and to needs to be replaced.

Keeping Equipment in Tip Top Shape

At the beginning of the day and at the end of the day, its important to look over your equipment and make sure everything looks correct. If your unsure, ask your team. If you are by yourself, double check your manual for the type of equipment you’re using. This way you will have lesser chances of having these common welding issues.

Have questions? Contact us, we are willing to help you. We want you to be satisfied with your finished work.