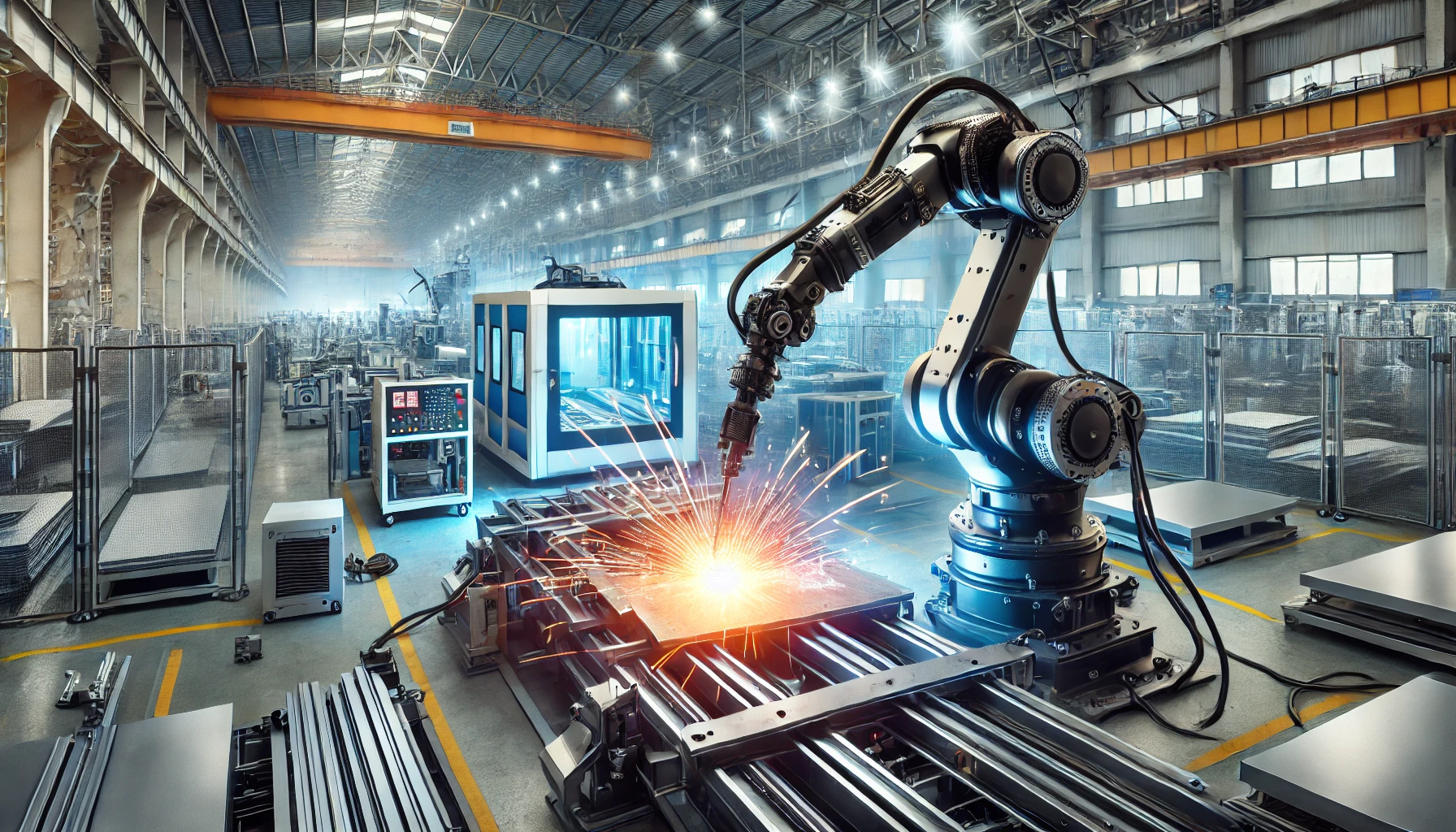

Understanding the sheet metal theory is imperative to great welding and engineering experience. Since sheet metal contributes to the most significant percentage of metalworking processes, every welder should have a definite knowledge of this subject.

Sheet metal is simply any piece of metal with a width ranging between 0.5 and 6mm. This width is what defines sheet metal thickness.

Any piece exceeding 6mm is known as plate metal, while that with a thickness of less than 0.5mm is known as foil metal.

What is Gauge in Sheet Metal Thickness?

Gauge is a popular term used to refer to metal thickness. However, different metals might have the same thickness but different gauge. For example, a 6mm aluminum sheet has a different gauge compared to a similar-sized sheet galvanized steel.

The term gauge is popular in North America. The majority of engineers use the gauge to refer to metal thickness.

Gauge (Ga.) is a unit for measuring diameter. It represents metal thickness in relation to the weight per square foot. A small gauge means a larger diameter and consequently larger thickness and vice versa.

Ferrous and non-ferrous metals of the same thickness have a different gauge. The sheet metal gauge chart, however, has gauges for different metals.

Standard steel with 10 gauge has a thickness of 3.416 while aluminum, brass, and copper of similar gauge have a thickness of 2.88mm. Also, standard steel of 20 gauge has a thickness of 0.912 mm while the non-ferrous counterparts have a thickness of 0.813mm.

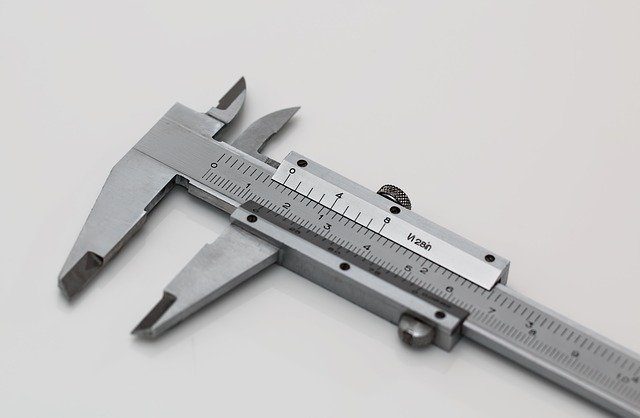

Measuring Sheet Metal Thickness

Generally, there is no standard of conversion between metal thicknesses in inches to gauge. To calculate sheet metal gauge, you have to measure its thickness using a tape. Using a sheet metal gauge, you can match the thickness to the appropriate gauge on the chart.

Sheet metal is often formed into flat pieces and rolled for transportation. Sheet metal can either be formed through hot or cold rolling.

Metal gauge, however, has a tolerance range to allow a slight thickness variation. This is the ultimate formula for measuring steel metal thickness;

Identifying the Type of Steel

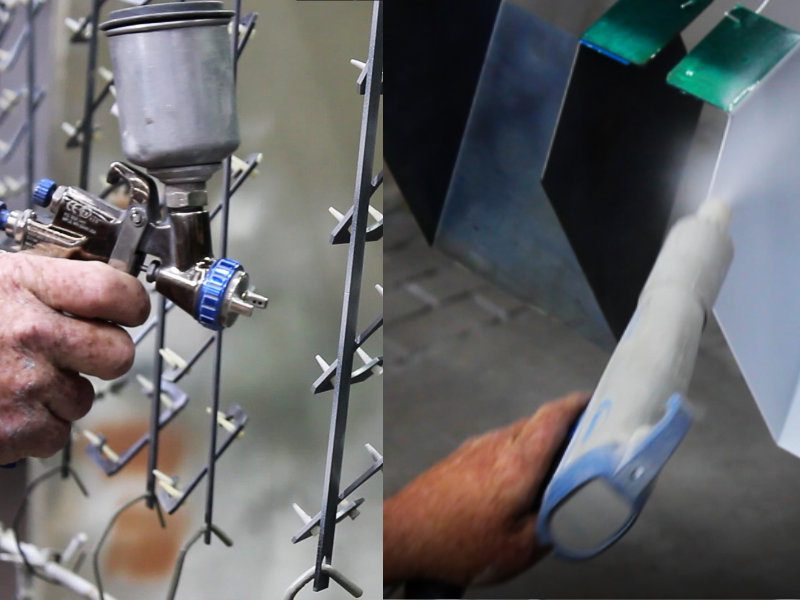

Generally, the majority of steel that you will come across is always cold-rolled. This type of steel has no coating or chemical additives. However, galvanized sheet metal has a 0.001-inch zinc coating. On the other hand, stainless steel has a chromium addition to reducing corrosion.

Cut a Square-Foot Sample

To get an accurate measurement, cut a square-foot piece. This square-foot piece helps calculation of thickness easier. Weighing a larger or smaller piece will lead to extra calculations.

Weigh the Steel Metal

Measure the weight and convert it to a pound per square foot. The weight and gauge number of steel are closely related. The Manufacturer’s Standard Gauge for Sheet Steel is 41.82 pounds per square foot.

Calculating Gauge in Inches

Divide your figure by 41.82, and you will have arrived at the steel metal gauge as measured in inches. While referring to the U.S Standard gauge for sheet steel, you will establish the accurate metal gauge of the above steel metal.

This process is, however, slightly different for metal, such as aluminum, brass, copper, zinc, lead, and aluminum alloys.

Why is Determining Sheet Metal Thickness Important?

Nearly all metalworking processes rely on sheet metal thickness to achieve various processes. Whether you are working with galvanized steel, standard steel, or non-ferrous metals such as aluminum, brass and copper, sheet metal thickness is a mandatory parameter in any metal fabrication process.

The Bottom Line

Up to now, you have all the relevant info on sheet metal thickness. As long as you have the accurate parameters, no metal fabrication process can stand your way. For any help on metal fabrication, consult our experts, and we will be willing to help.

{{cta(‘1615cd3c-4bbe-4d95-8408-39a73e91a111′,’justifycenter’)}}